The Dotson Cabin: Identifying the Builder’s Tool Cache

by Steve Douglas

A edited version of this article was printed in the June 2020 issue of The Beulah Newspaper. Below if the full version with more details.

My interest in old hand tools, log cabins, as well as the people that built and lived in them a century or more ago has developed over my entire adult life. I’ve repaired a couple of log cabins, lived in a Wyoming homestead cabin (1976-1980) and collected many examples of tools used in log cabin construction. I’ve been aware of efforts to move and restore the Dotson Cabin from the 3-R Ranch to a new site in Beulah, but until recently have not been involved in that process. (See The Beulah Newspaper’s December 2018 edition and the “Dotson Cabin Virtual Tour / Beulah Heritage & Preservation League” on-line for background.) I had occasion to speak with Joe Arrigo about the project last September. He mentioned the need for some tools like those used to build the cabin, primarily to further the educational value of the cabin once the restoration is complete. I told him I would be pleased to help with that.

Good, old tools can be hard to find. I set three criteria for the Dotson Cabin tool cache, those being:

1. Identify the types of tools that likely would have been used,

2. Identify tool manufacturers in business around the time the Dotson Cabin was built, and

3. Collect examples of those tools (by time-relevant manufacturers) that are still in good condition so that, if need be, they could be used in actual demonstrations of log cabin building techniques.

Gathering those tools was an interesting process. Many of them I already had. For those I didn’t, E-Bay helped fill the gaps. I also turned to on-line information sources to learn about tool manufacturers and their histories. It was a fun process!

To begin with, a ready source of straight logs of minimal taper and appropriate diameter was needed. The cabin’s size suggests that at least 40 trees (10” diameter) were needed for the walls and beams, and another 40 (4” diameter) for the rafters. Today, the ponderosa pine forest begins about 300 yards west of the old Dotson Cabin site and could have been about the same in 1870-71, when it is estimated the logs were cut. Felling those trees would probably have been done with a two-man crosscut saw and an axe. The logs could have been skidded to the cabin site or moved in winter with a sled, using horses or oxen.

Let’s look at the Dotson Cabin and see what it tells us from its design and tool marks. I will focus mainly on the original cabin and not get into its later additions and renovations. The original cabin is one story with two rooms, measuring about 17’ wide by 45’ long. It is made of straight, hand hewn ponderosa pine (based on remaining bark) logs, stacked 10 logs high to make 10’ high walls. Most logs were 9-10” in diameter and have relatively minimal taper from end to end. Two sides (in and out) of the logs are hewn to widths of 5-6”. Axe marks on the logs indicate that most of the final work was done with a standard double- or single-bit axe, although some are long enough to have been made with a broad axe. A broad axe may have been used more in the early stages of hewing. The final hewing was done by a skilled person, using firm, measured and consistent strokes with sharp tools. The top and bottom edges of the logs were generally not hewn and the bark was left on. Gross chinking between the logs was done with wedge shaped strips of wood, with gaps then filled with a mixture of mud and straw (according to Joe Arrigo). The cabin’s four corners were expertly notched in a dovetail style, which is excellent for stability and for shedding moisture that would otherwise accumulate in the notches and cause rot. The logs that form the interior wall are joined to the outer walls with square notches. Tool marks indicate that the notches were made with a cross-cut saw (one man?) and axe. Then they may have been finished with flat and corner style framing chisels, and a mallet. Uneven corners would have been finished with something like a one-man cross-cut saw, making square ends. Except for the top logs, nothing but gravity and dovetail notches was used to hold the logs together.

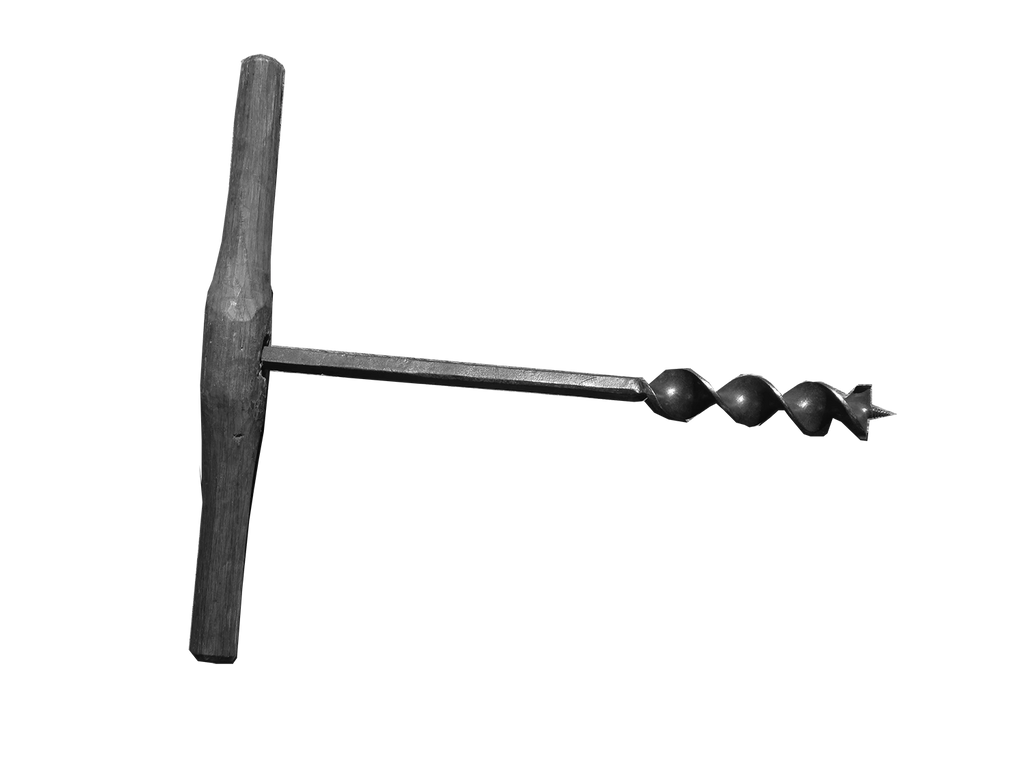

The top logs were secured to the one immediately below them with wood pegs (made of Osage Orange) driven in holes probably drilled with a 1 ½” diameter T-handled auger. The wood pegs may have been shaped to fit with a hatchet or draw knife. Likewise, a broad hatchet may have been used for finish work on notches and elsewhere. Some rough-cut lumber was used in the cabin’s construction for window and door frames, and (based on the illustration and text in the December, 2018 Beulah Newspaper article) for the roof and plank floor. The roof was finished with milled cedar shingles. It appears that the only nails used in the original construction were square nails to secure the rafters, window and door trim, and roofing shingles.

It is interesting to note that reportedly, General William Jackson Palmer founded the Colorado Coal and Iron Company (predecessor to CF&I) in 1872, but according to Wikipedia “The first, and only until World War II, integrated iron and steel mill west of St. Louis was built in 1881 in Pueblo on the south side of the Arkansas River by the Colorado Coal and Iron Company(CC&I)” Among other things, it produced square nails, but square nails used in the initial construction of the Dotson Cabin were probably shipped by wagon from St. Louis or somewhere east of the Mississippi River. (The Transcontinental Railroad was completed May 10, 1869, but it did not come through Colorado; instead, it passed north of us through Wyoming.) Also, on a note of local interest, in 1857 William Kelly patented the Kelly Air Boiling Process for refining iron, which evolved into the Kelly-Bessemer process used by CF&I in Pueblo. The same William Kelly began manufacturing axes in the 1870’s, which is why I chose Kelly axes for this tool cache. The post-Civil War years of 1865-1890 saw a lot of innovation in tool making, which was likely reflected in the hand tools used to initially build and then add on to and renovate the Dotson Cabin. The marks are right in front of us, thanks to the original builders and now, Reeves & Betsy Brown, the Beulah Heritage & Preservation League, Pueblo School District 70, Joe Arrigo and lots of other fine folks.

TOOLS IN THE CACHE, POTENTIALLY USED FOR INITIAL CONSRUCTION ARE:

Two-Man Crosscut Saw (54”) and 2 carpenter’s saws (rip, patented 1874 & crosscut) – all by Henry Disston & Sons of Philadelphia, founded in 1840

Broad Axe – appears to be hand forged, blade = 11” wide, overall length = 38””

One-Man Crosscut Saw (42”) - by Curtis Saw Company – St. Louis, Mo … established 1854

T-Handle Auger with 1 3/8” bit and home-made handle, makers mark on bit unreadable

10. T-Handle Auger with 1 ½” bit and factory handle by PS & W, Patented March 20, 1888

Claw Hammer and Roofing Half-Hatchet - no makers mark on either

Other tools in the cache that were potentially used for additions, remodels and general tasks around the Dotson Cabin are braces (drills) and auger bits, a Breast and Shoulder drill, lathing hatchet, flooring hatchet, folding ruler, buck saw, wooden D-Handle shovel and fencing pliers. All of these tools will be donated to the Beulah

Copyright © 2023 Dotson Cabin Preservation League - All Rights Reserved.

Website created by G. Wiz! and maintained by the Dotson Cabin Preservation League